For this entire week, we have been hard at work getting our first prototype ready for Max and Joyce’s visit to Oahu on October 15th. This involved lots of 3D printed parts, sourcing aluminum/steel parts for the frame, and casting the rubber urethane rollers.

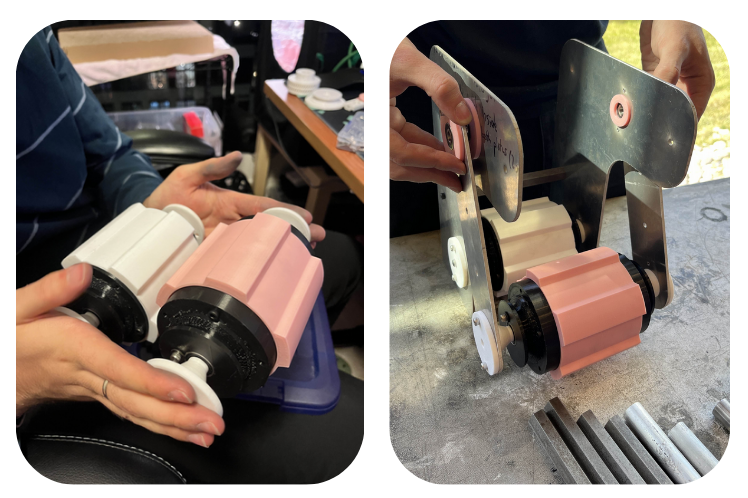

Assembling the frame and rollers.

Assembling the frame and rollers.

After attaching the belt system and a drill, the rollers could successfully be spun! Here is a demo of the prototype in action:

Unfortunately, despite the hard work of Daniel Ye, the motor system was not ready by the first trip to Oahu, Hawaii. The motor could be operated on its own using closed-loop speed control, but after attaching to the system, we learned that it was too weak and could not adequately drive the rollers.

Oahu Trip

The primary purpose of this initial trip is to gather data that would help us best move forward with designs. Some of the qualitative and quantitative data we aim to collect include:

- Force required to picking the plants

- Average size/shape of plants

- Effectiveness of roller mechanisms

- Optimal speed of rollers

- Effectiveness of claw mechanisms

- and more…

Stay tuned for updates from our trip! 😎