Max and Joyce have been hard at work brainstorming and creating CAD models for different harvester designs! Here are our candidate ideas.

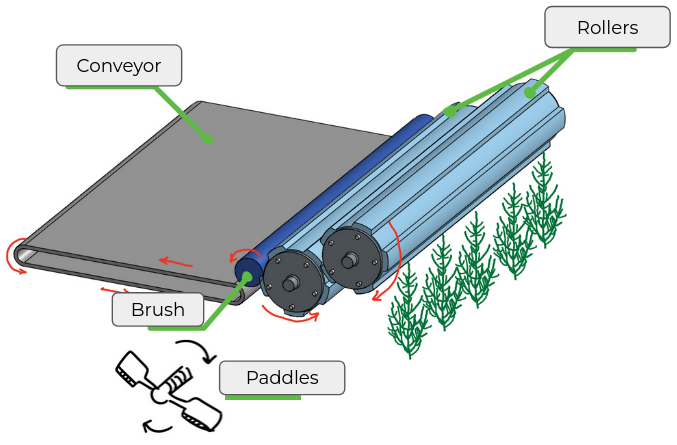

Two rubber rollers pinch the plants and pull off the tips as the machine moves across the farm.

Two rubber rollers pinch the plants and pull off the tips as the machine moves across the farm.

This first idea consists of two rubber rollers rotating in opposite directions. If the implementation is successful, this idea would perform well in terms of speed and reliability.

However, our concern is that the yield would be low for this design. Since sea asparagus grows in a shrub-like shape, the rollers would only graze over the top of the plants and ignore the plant tips lower down.

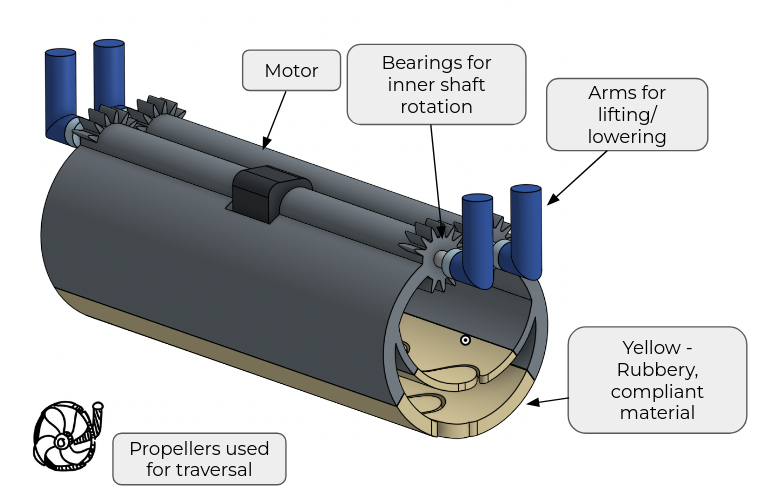

A claw-like grabber grips onto the plant and pulls upwards.

A claw-like grabber grips onto the plant and pulls upwards.

This second idea consists of claw with soft rubber material at its tips as to not pinch the plants. This design mimics the manual picking motion the best, where a human grips the plant and pulls upwards.

The downside to this design is that the speed is low, comparable to that of a human picking. Lowering/lifting the claw as well as repositioning to every plant takes time.

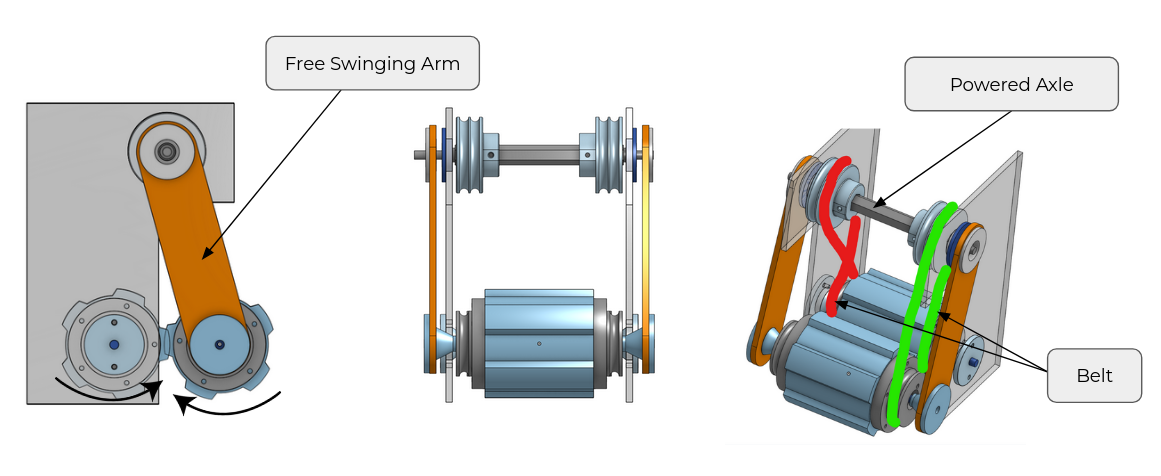

A set of movable rollers pinch onto the plants and use rotational motion to pull off plant tips.

A set of movable rollers pinch onto the plants and use rotational motion to pull off plant tips.

The third idea acts like a combination of the first and second ideas with movable rollers. One of the rollers pinches onto another, which then start rolling to pinch the plants. This option provides a balance between good yield and speed.

The downside with using movable rollers is added complexity. This design has many more degrees of movement, requiring more motors and more complex hardware to support it.

Despite the complexity, this third design is still the team’s favourite so far, and will likely be the first testing prototype during our first trip to Hawaii.